Industry: Household Appliance/Industrial Equipment/Magnetic Charging

Problem: Corrosion of NdFeB magnets

NdFeB magnets are also called rare earth permanent magnet, which is currently the material with the highest magnetic energy product in the world. NdFeB magnets are widely used in electronic products, such as hard drives, mobile phones, headphones, and battery-powered tools.

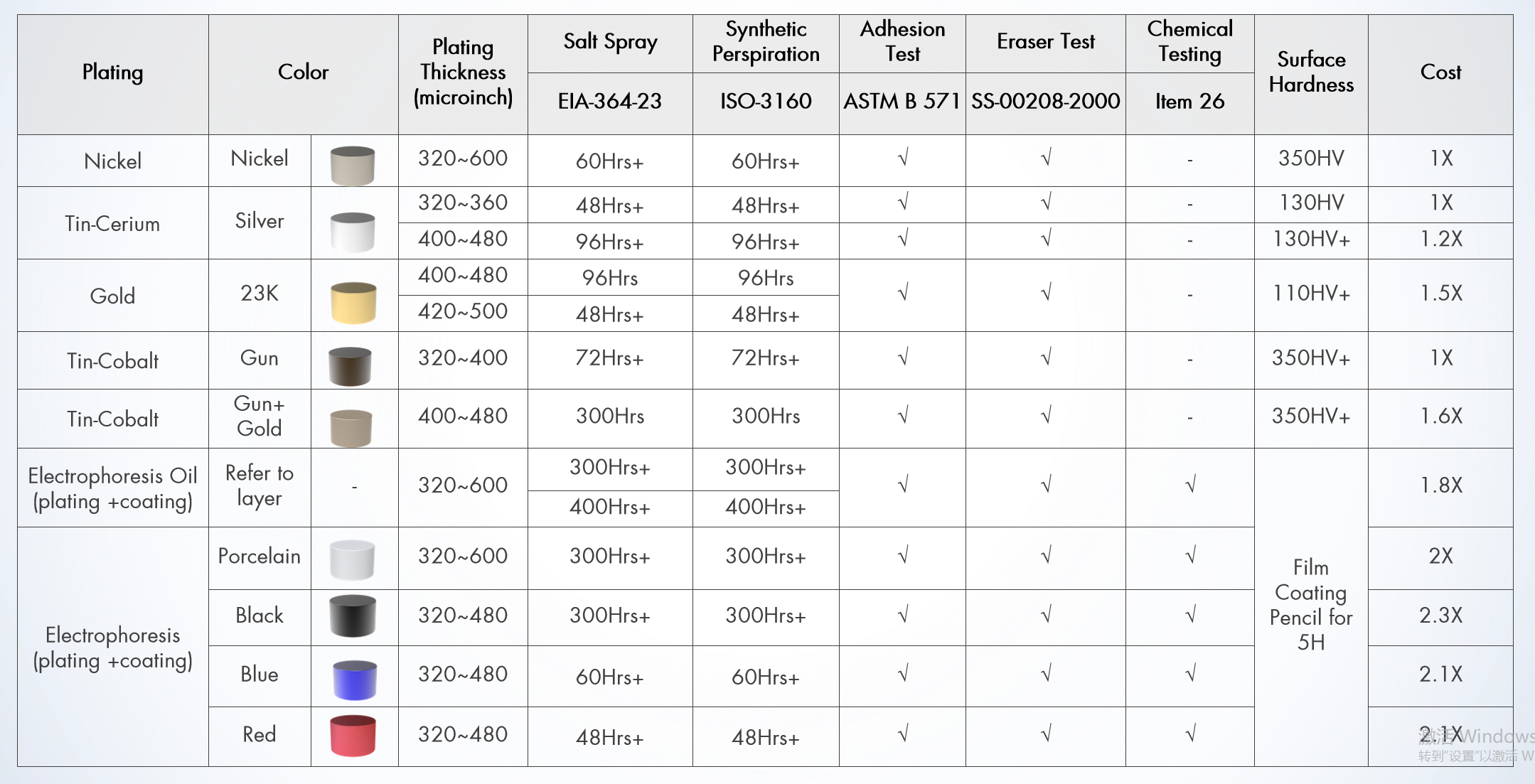

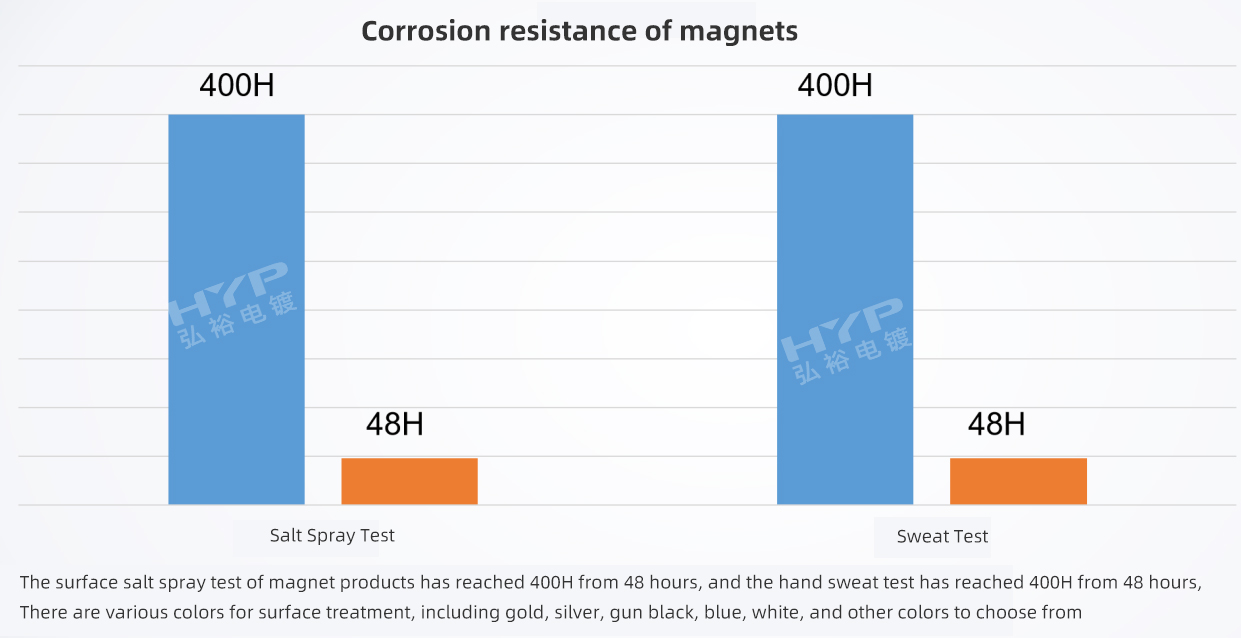

Due to the susceptibility of NdFeB magnets to corrosion, protective treatment is required on the surface of the magnet to avoid corrosion damage. This can be achieved through electroplating with gold, nickel, zinc, tin, or surface coating with epoxy resin.Different electroplating solutions can achieve different functional effects,as shown in the table below. HYP magnet salt spray test can reach up to 400hours in 48 hours, and hand sweat test can reach up to 400H in 48 hours.

HYP has also developed many special coatings to meet specific color requirements for electroplating surfaces, such as different colors of gold, red, black, blue, white, etc., to meet the needs of different application scenarios.